“HOW IT’S DONE”

Have you ever wondered about the process of how handmade items in textile arts are created? Plant or animal fibers have been used to construct functional or decorative objects since the beginning of civilization. Over the course of history, the methods and materials employed have changed greatly but the overall function of textiles remained mostly constant. This blog series will include a bit of history, a few essays, and free video lessons on How It’s Done.

THE TEXTILES OF PERU

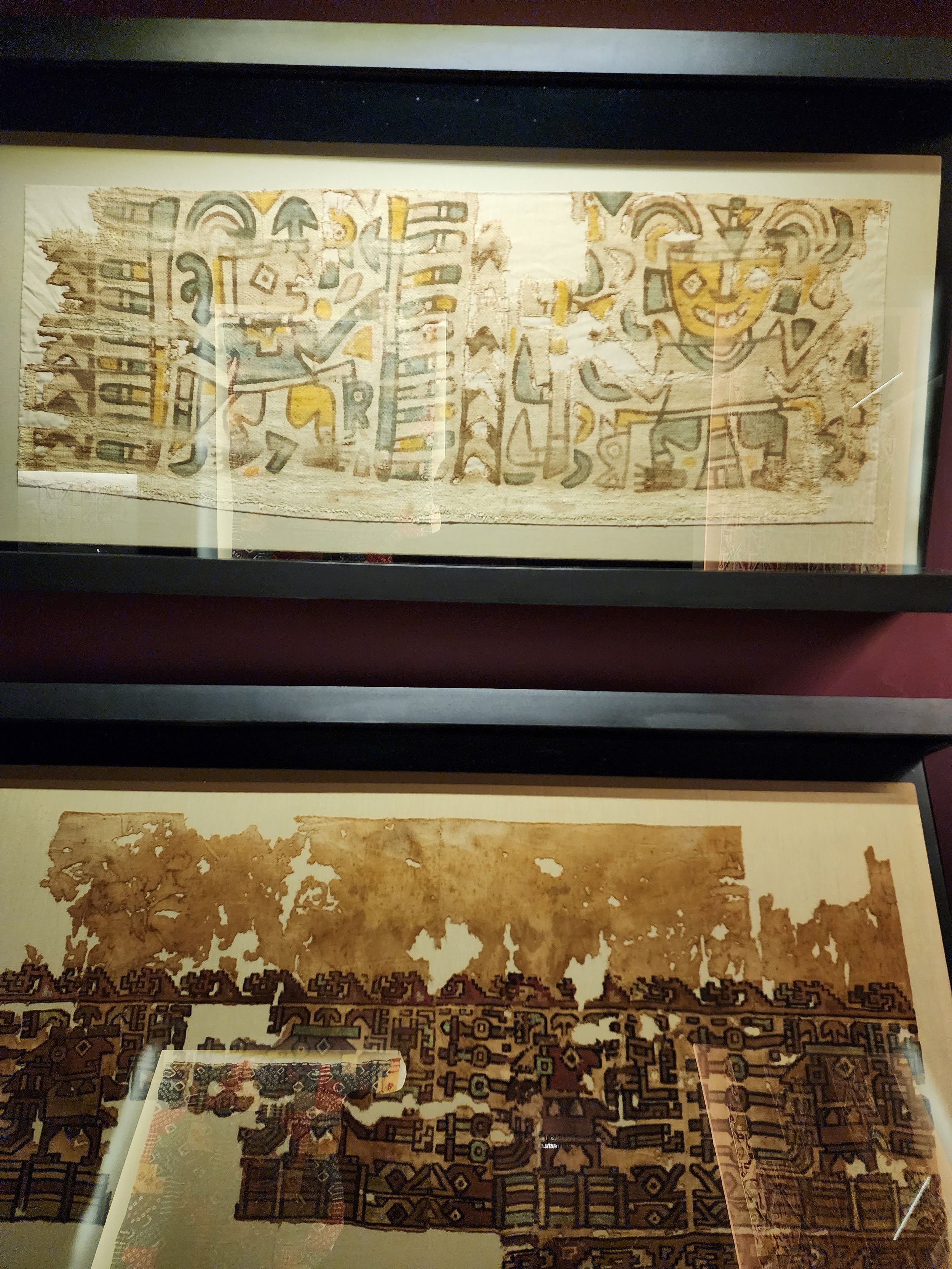

A pre-Columbian textile piece from the Amano Museo, Lima, Peru.

Machu Picchu

¡Hola!

When traveling through Peru, the words that come to mind are vibrant, colorful, and ancient. As a fiber artist, historian, and former alpaca owner, I wanted to take a closer look at the people who are continuing a textile tradition that has been handed down through the generations for thousands of years. There are no written records for the transmission of skills or patterns of the Native peoples. All designs are woven from memory.

The Quechua weavers are known for their colorful and mesmerizing patterns in woven fabric. Every step in creating their textiles is purposeful. They begin with shearing and processing the raw alpaca fiber by hand. Naturally occurring detergent plants like Sacha Paraqay root & Illmanke are used to wash wool and alpaca fiber. Once dried, the fiber is spun into threads on hand spindles. Plants, minerals, and insects are collected and prepared to dye the handspun yarn. Generations of knowledge are passed down through families that dictate the direction yarn is spun, how the warp is set up, and how to create patterns for designs that befit the fabric’s purpose. The woven fabric is embedded with meaning, stories, and history.

Quechua is the language spoken by the Inca and remains one of the major languages spoken by the native peoples in the highlands of Peru. However, their traditions reach further back than the Incas to pre-Columbian times. I was fortunate to have spent a day learning about the process of creating textiles according to their traditions with two talented women from the Parobamba District. A friend and I were taken for a walk into the woods to pick leaves for a dye. Through an interpreter, the women pointed out numerous plants that were used for teas, medicines, and dyes. We were shown how to pick Ñuñunqa leaves so that the plant remains healthy and how to prepare the leaves for the dye pot. We also chose leaves for a lovely tea before getting to work.

The stove and pots were made of clay, giving off a comforting scent of burning wood in the outdoor kitchen. I dropped sample skeins into two dye pots, one with Ñuñunqa leaves making a yellow but changed to a subtle green after adding a mineral salt. The other dye was red derived from the cochineal beetle found on cactus leaves. While the leaves were doing their magic to color the yarn, spindles were brought out. I usually spin wool on a spinning wheel. Occasionally, I use a spindle but not the same type as the Andean women. They can spin standing, walking, sitting, and probably in their sleep! Let’s just say, I have a lot of practice ahead of me.

My weaving experience has been primarily with peg looms and frame looms. This past year I have been learning to weave on the inkle and rigid heddle looms. The Quechua women use a back strap loom. There are many similarities between these types of looms but the major difference I observed is in the materials used. The weavers of the Andean Highlands use what they find in nature. Nothing is manufactured or purchased ready-made. The warp is set up in a specific manner of color on wood stakes, pounded into the ground with a large rock. Wood poles and sticks are used for the frame, shed, pick-up stick, heddles, and shuttles. An alpaca bone is used to separate yarns and packing picks or rows of woven thread.

One end of the loom is tied to a post or other stationary object and the other end is attached to a woven strap that goes around a person’s back and is attached to the bottom wood beam of the loom. The tension is controlled by the movement of the weaver leaning forward or backward. After all the preparation, the magic begins. I cannot adequately describe the weaving abilities I observed, much less attempt to replicate them! The patterns are memorized, and their fingers work faster than my eyes can track the individual strands of yarn they pick. [See video] It was like magic. Patterns emerged in beautiful arrangements of color and design, drawing from ancestral traditions as they weave. The Andean culture is a textile artist’s dream. The tradition, expertise, beauty, and quality of the work is beyond remarkable. If the opportunity to visit Peru arises, I highly recommend it.

Here are the most memorable textile activities and places I experienced during my trip to Peru:

1) The Center for Traditional Textiles of Cusco. < https://textilescusco.org/>This center was established in 1996 by a group of Chinchero weavers to breathe new life into the weaving traditions that were slowly being forgotten. The weaving center is led by author and Quechua master weaver Nilda Callañaupa Alvarez.

2) Weaving Workshop – Experience the Magic of Andean Textiles booked through TripAdvisor (Peru Private Tours) < https://www.tripadvisor.com/AttractionProductReview-g319822-d17418671-Experience_the_Magic_of_Andean_Textiles_Weaving_workshop_Cusco-Chinchero_Cusco_Reg.html>

3) The AMANO Museo Textil Precolombino. < http://eng.museoamano.org/exhibitions/ > This museum highlights pre-Columbian textiles from the private collection of Mr. Yoshitaro Amano. Though the museum is small, I spent hours exploring the development of weaving on display.

Thank you to Wade Gease, aka The Alpaca Guy, for the work you put into offering an exciting and educational experience highlighting the best of Peru. <https://www.thealpacaguy.com/peru-trips-c1igg>

Quechau Weaver near Cusco, Peru

Hidden Gems

Harvesting mushrooms for natural dyes.

Colors in the Woodlands of Northwest Minnesota

The Upstream Minnesota fellowship was an excellent opportunity to explore my favorite places in Minnesota and integrate my love of the woods with my art. For my project, I foraged for natural materials to use in creating dyes for wool. Here is a brief video summary of my experience.

Sustainable Fiber Arts

Join Aliza Novacek-Olson, a former history professor and fiber artist, as she takes you on a journey through the fascinating world of sustainable spinning and fiber arts. Inspired by her grandmother's crochet skills, Aliza embarked on a fulfilling journey to master spinning and other fiber arts techniques.

In this video, Aliza shares her passion for spinning, weaving, felting, and more. She explores the historical context of these crafts and how they connect us to the earth and its resources. Through her experiences with alpacas, llamas, and angora rabbits, Aliza demonstrates how using your own fibers can be both sustainable and rewarding.

Thank you to Sarah Hand and Bryce Payne from the Steffes Group, Inc. out of Fargo, ND for their excellent work in interviewing, filming and producing this video blog. They were so fun to work with and showed genuine interest in the traditional fiber arts. Watch this YouTube video for an overview of traditional work with textiles.

A glimpse of Spinning Wool

Scandinavian Festival Spinning Demonstration in Malung

A small community in Malung, just outside of Roseau Minnesota, is known for having a strong Scandinavian heritage. This past month, they hosted the first Scandinavian Festival. It was an amazing event with decorations, local artisans, music, programs, and of course traditional Scandinavian food! Here is a link to the Malung Community Center Facebook site if you are interested in seeing pictures of the events. A friend and I donned our traditional folk wear called bunads and demonstrated spinning. The short video shows spinning on a traditional wheel circa the 1880s and a modern spinning wheel.

A brief video of spinning wool on a traditional spinning wheel and a modern spinning wheel. Demonstrators are wearing bunads, a traditional Scandinavian folk costume.

Indigo Dyeing

Indigo dyed textiles.

Indigo is a natural process of dyeing textiles that has been dated to 6,000 years ago. The oldest known fabric dyed with this plant was found in Peru. Indigo is extracted from a plant and goes through a fermentation process to produce its vivid blue color. Historically, indigo is used in dyeing wool, silk, and cotton. Most indigo dye used today is a synthetic dye, and not the traditional dye made from plant materials.

Indigo plant

Photographer unknown licensed under CCBY-SA

Carding Wool

How to card wool in preparation for spinning or felting.

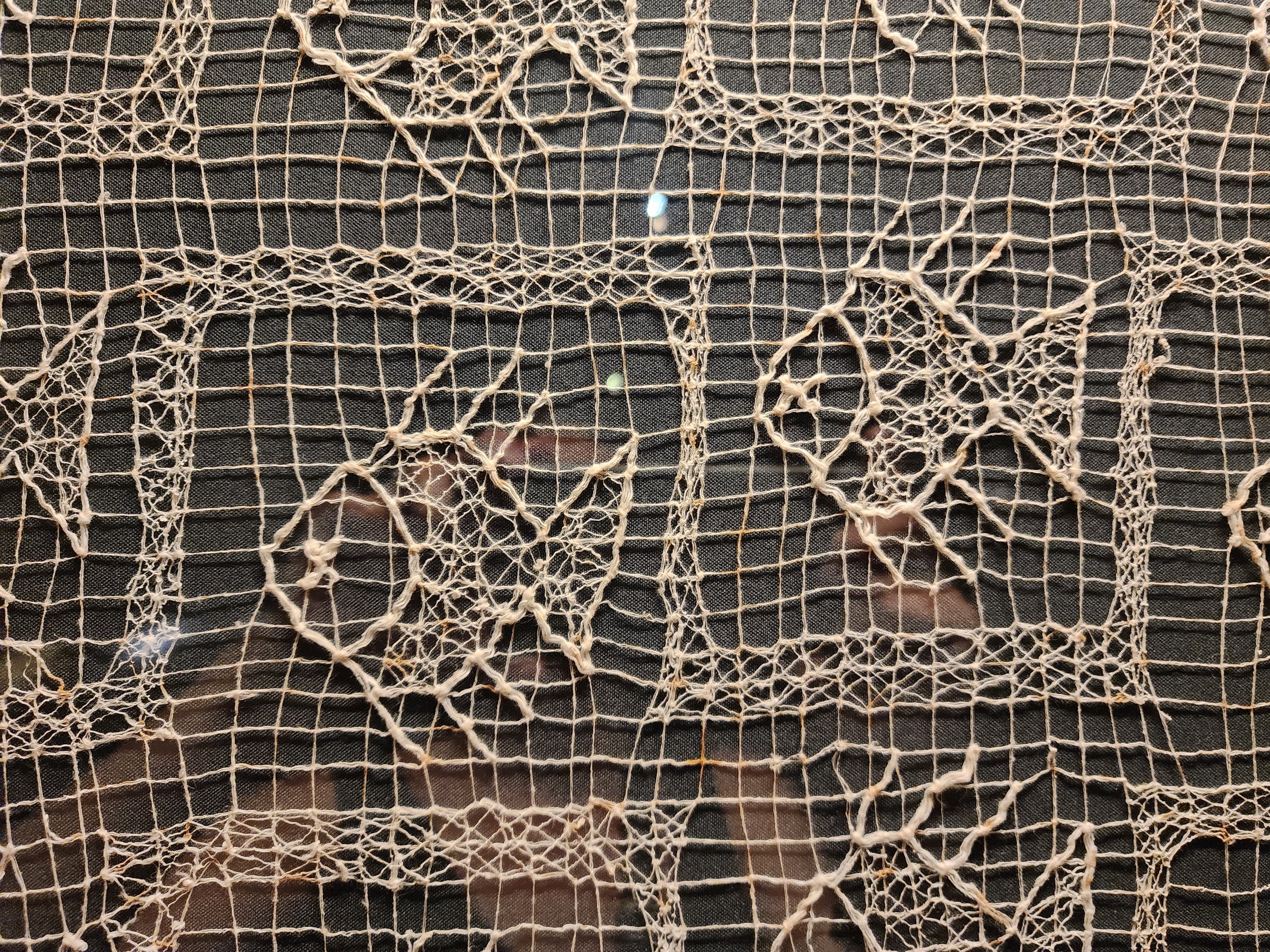

After shearing sheep or other fiber bearing animal, there are several steps that need to be taken for the wool to be usable for spinning or felting. After shearing, skirting, picking, washing (also called scouring), drying, then comes carding or combing. This brief introduction is for carding wool using hand cards.

Wool carding is an ancient process by which wool or other fibers like alpaca are separated and then brushed out on two carding paddles (much like dog brushes) to straighten out the fibers. Once carded the fibers are ready for spinning.

Wool Carders in a basket of llama fiber.

Shearing an Alpaca

How shearing an alpaca is done.

Alpacas need to be sheared every year. It is not a painful process. It is an alpaca haircut and it relieves the alpaca from the hot heavy fiber. However, like humans, some alpacas have irrational fears. For instance, the sound of a dentist’s drill can set my heart to palpating! Well, in this video you will see Leo get sheared. He is afraid of the sound of the clippers. In the background you will hear some screaming and you will see a sock over his mouth. The sock catches the nasty smelling spit that alpacas can do when they are afraid or mad. No harm comes to the animal in the process of this video.

Notice where the shearer begins? He starts at the side of the animal’s stomach and shears with one neat pass from top to bottom. The continuous path prevents second cuts - when the blade is lifted and placed down again , then re-cutting an area already done which leaves very short lengths that forms little pills when felted or carded for yarn. The shearer progresses across the top of the back to the other side. The fiber is dropped onto a clean bed sheet. This portion of fiber is what is referred to as the “barrel.” It is the best cut of fiber from each animal.

Fiber has a grading system from prime (the barrel section), seconds and thirds. Prime fiber is valued higher for the softness and staple length. It is the part that is soft enough to comfortably lay against a person’s skin when in a textile form. In young animals, the neck fiber can be as good as the barrel, but it needs to be checked. This is the reason that it is collected separate.

Some of the public demonstrations (see gallery for pictures) were funded by a state arts grant. I appreciate the help in bringing more fiber arts to my community!

Aliza Novacek-Olson is a fiscal year 2023 recipient of a Creative Support for Individuals grant from the Minnesota State Arts Board. This activity is made possible by the voters of Minnesota through a grant from the Minnesota State Arts Board, thanks to a legislative appropriation from the arts and cultural heritage fund.